Sunday, 31 July 2022

Survey Vessel Jean Bourdon

CLC's Office Building

The CLC office building was located just west of a bottling works (Horne's 1910-1940's) and tenements on Ontario Street. Circa 1949 aerial view showing the office, store, and tenements (above) and a 1950's aerial view, with arrow showing the office across Ontario Street from the plant buildings:

The office building was sold to Empire Life Insurance in the early 1960's, as the office staff had moved into the works office on the William Street end of the plant buildings, by 1955. Plant operations ceased on July 1, 1969, and the plant buildings were demolished in 1971.

Marc Shaw kindly shared his photo of the CLC office building in its death throes, with Doornekamp doing what it did. The office disappeared, becoming just a memory on the current Empire Life Insurance parking lot after 1994.

Saturday, 30 July 2022

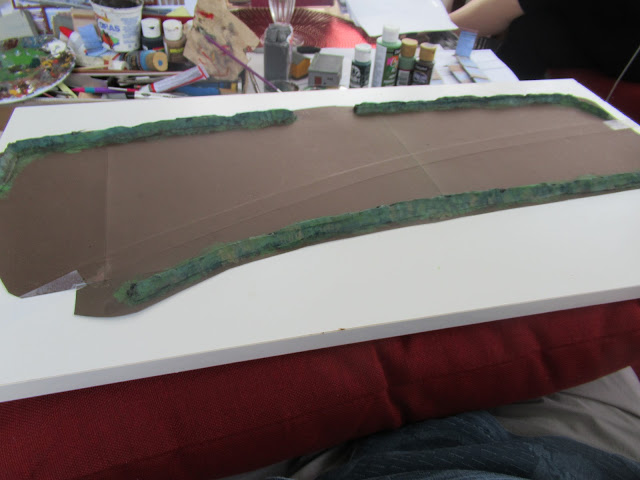

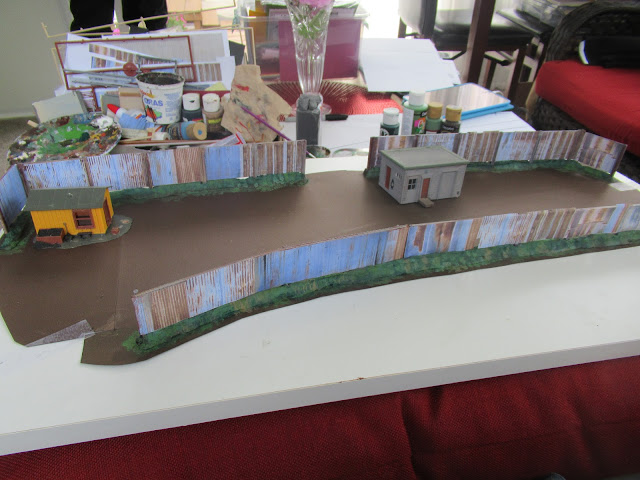

Modelling Tannery Effluent

Tuesday, 26 July 2022

Ontario Street Tenements

Being two blocks west of City Hall, it's not as if these tenements were hidden from view. In fact, then-Mayor Bob Fray was accompanied by a Whig reporter and photographer in 1965 and 1968 for two stories tracking progress made in low-income housing.

For the 1968 report, walking down Ontario Street, the former Anglo-American Hotel at 172 Ontario (and Johnson Street), the McNevin property next-door "rat-infested, boarded-up' and the 'just a stiff breeze away from falling-down' tenement from which the Mayor appears to be running while the reporter tarries (top photo). In 1968, two families still lived in the laundry-lined building with its neighbouring building with its boarded up windows, with the other two units empty.

Yes, this was really realty reality.

Photos in this post from Queen's University Archives.

Monday, 11 July 2022

Modelling the I.Cohen Scrapyard

.JPG)

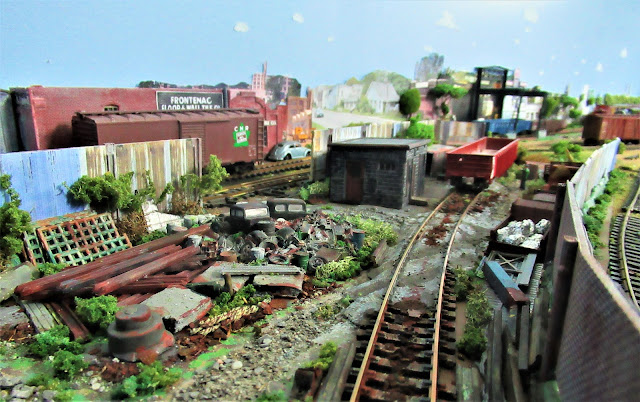

Along-the-spur views - from the turnout end of the spur (above) with jointly-served industries Frontenac Floor & Wall Tile and Presland Iron & Steel in background. The end of the spur (below) with Gus Marker and Frontenac in the background. All that remains is to add a tracked crane to move that scrap around, figures and final scenery and figures.

I deconstructed a Life-Like rail crane, gluing the cab on tracks from a Majorette excavator, painting and adding Browning lettering to the back of the cab. Two metal figures look workmanlike enough to find their way into the scrapyard scene!

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)