The Kingston gas works operated for over 100 years from 1848 to 1957 on a 1.6 hectare site located north and south of Barrack Street between King Street East and Ontario Street, and Queen Street and Place D'Armes. Two gasification tanks loom over downtown, in the background behind Millard & Lumb, with the Richardson elevator demolished in 1941 still standing (top photo - Queen's University Archives, V23-IndB, Kingston Picture Collection, Industrial Buildings).

The main gas works site was later occupied by the PUC bus repair garage, parking lot, and office, the Kingston police underground parking garage, a Kingston Hydro substation, and retail stores. The auxiliary gas holding area was occupied by the PUC bus transit garage and parking lot. The city property was also the site of Kingston Transit System garages and the Kingston Police headquarters. The former gas works site is located about 150 metres southwest of the mouth of the Great Cataraqui River. (Below - a 1950 aerial view showing the older tank dismantled, new propane tanks installed, with the PUC building at left, Millard & Lumb at right, and Fort Frontenac at bottom - Queen's University Archives, V25-6-2-37, George E.O. Lilley Fonds, Aerial Photographs Binder.)

In its day, the Kingston plant was the third largest in Ontario. By 1905, 800 million cubic-metres of gas were being produced yearly, with 1,573 gas meters in operation. The location, as with most other gas works, were usually chosen to keep pipe runs to downtown customers short. Gas was used for lighting and heating, often requiring nearby water access and docks. The first gas jet (in all of Ontario) was lit in the window of the Wilson building on Wellington Street in 1847.

TIMELINE

Dating to 1848, a coal gasification plant in the King-Queen-Ontario-Place d’Armes block was operated by the Kingston Gas Light Company in 1864, the City by 1905 and the PUC in 1914. Coal arriving by boat would total 10-15,000 tons per year. Served by a CN spur crossing Barrack Street north of Ontario Street, cars of coal were unloaded for gasification, the production of a gaseous fuel, with ashes and inert matter remaining as residue. A nearby wall sign proclaimed “Gas – The Modern Fuel”. The main gas works was south of Barrack Street, with the large gas-holding tank north of Barrack Street, dominating the downtown site. Gas production evolved from retort coal gasification, to a carbureted water gas process in 1925. The rise of oil slackened demand through the 1930’s.

The coal gas plant was later abandoned, superseded by a propane air mix plant. Propane tanks on flat cars were delivered via the spur from Horton Steel Works of Fort Erie, ON in March, 1950. Tank cars (8,000 gallons each) were unloaded into the tanks on the PUC spur, that had crossed Barrack Street (1947 fire insurance map image - above) later truncated at Barrack Street. The old gasification tanks were being demolished in the fall of 1950 by former builder George Boyd. The tanks were made of quarter-inch riveted plates, cut apart by torches under water to reduce the danger of sparks from any residual gas. The resulting scrap weighed 200-300 tons. The older 48 year-old 'purification' tank was 50 feet high and 75 feet in diameter. The 35 year-old 'storage' tank was the same height and 100 feet in diameter, to be demolished in 1951.

All the way from Fort Erie, ON - Horton Steel Works propane tanks being unloaded from flat cars at the site in February or March, 1950. An interesting time of transition - the larger tank is still pending demolition (above and below - Queen's University Archives, V25-5-11-197, George E.O. Lilley Fonds).The new propane tanks are in place in April, 1951. Millard & Lumb is shown at right (Queen's University Archives, V25-5-15-5, George E.O. Lilley Fonds).

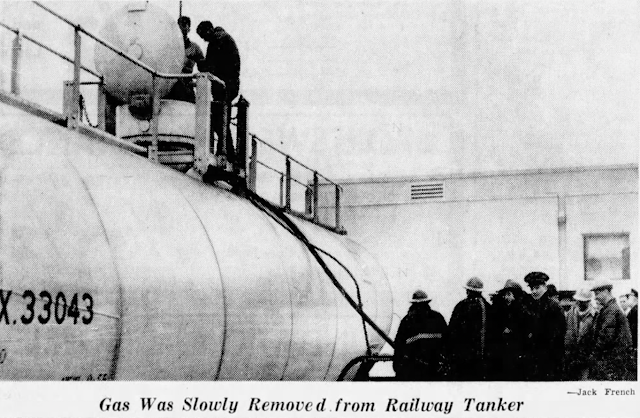

Propane almost ran out on February 18, 1958 during a severe cold spell. More was needed, but CN had no loaded propane cars available in Kingston for the PUC. There were cars in Belleville and Brockville. An urgent call was placed to CN, and one car was quickly despatched from Belleville and unloaded. Two more cars arrived in Kingston soon thereafter.

In 1958, Corcoran Excavating installed a five mile-long eight-inch gas line from the Trans-Canada pipeline just south of Glenburnie, along Perth Road and Division to Railway Street at Patrick Street, where it was connected to a 1956-built line from that intersection to the gas plant. The pipes were manufactured in 50-foot lengths by Page Hersey Tubes Ltd. in Welland, ON and supplied by Grinnell Co. of Montreal. The capacity of the completed line was 800,000 cubic feet per hour, and the cost was $250,000. A regulator station was built at Montreal and Railway Streets to supply industries in that area. (Below - Whig clipping fortuitously showing a CPR boxcar and the Sowards Coal office in background!)

The downtown spur was removed in 1970. The gas plant was to be moved outside the city in 1966, finally making the move to Lappan's Lane after 1968, due to the lack of a sewer onsite and a dispute with Kingston Township. The new four-tank site was to boost Kingston's gas supply from Trans-Canada Pipelines during peak usage periods. A CN spur was built just east of Lappan's Lane for $8,000, with gas mains laid along Counter Street off the Division Street gas main in 1967. This was part of a PUC service centre building for electric, water and gas departments (and later a bus garage) development on the site.

Coincidentally, the last car of natural gas at the downtown gas plant leaked. Much larger than the original 8,000 gallon cars, this one carried 27,000 gallons of propane. A fitting on the car's piping was the culprit, and it was towed into the nearby yard after its load was transferred to two onsite tanks. January 24, 1967 Whig clipping:

A final vestige removed - on September 28, 1970 a final gas holding tank was being removed from the site (Queen's University Archives, V25-5-39-103, George E.O. Lilley Fonds). Apparently photographed while waiting for the Flying Scotsman to arrive on the same day!

The new site in December 1991. One Procor and one CGTX propane tank car were spotted for unloading on the CN track designated KL03, just off Lappan's Lane and adjacent to Permanent Concrete. The silver bulk propane tanks are just visible on the PUC property at left:

The following original gasification structures are labelled by number on the two plant layouts shown below:

1. Generator House - used to make gas in a retort.

2. Oil tank - used for storage of oil (Bunker C) for water gas process or may have been used for tar storage.

3. Relief gas holding tank - used to store raw gas.

4. Condensor House - contained equipment to condense tars, oils and liquors from hot gases.

5. Purifier House - contains equipment to scrub raw gas to remove tars.

6. Main gas holding tank - used to store pure gas prior to distribution.

7. Meter House - used to regulate gas flow to consumers.

8. Coal Shed - used to store coal and coke.

9. Oxide Room - storage of new or spent oxide.

Fire insurance plans of site (above - 1908) and 1924 (below - 1924)

.jpeg)

No comments:

Post a Comment

I'm happy to hear from you. Got a comment about the Hanley Spur? Please sign your first name so I can respond better.