It is said, 'The more you know, the more you realize you have yet to know.' Having published posts on Kingston Shipyards and Canadian Dredge & Dock's small-vessel production, the Trent Port Historical Association recently posted some photos on social media of a large number of World War II tugboats built in Trenton, admittedly slightly west of the Hanley Spur, but just as interesting! Trenton's Central Bridge once covered 52 acres at West Street and Creelman Avenue (top photo) with rail access at bottom, centre of photo and the Trent River at top left.

Over several decades, beginning in 1937, the company was involved in such projects as bridges, airplane hangars, a Highway 401 overpass, a Thousand Islands tour boat and the Ontario Pavilion at Expo '67.

One of their largest contracts began in 1942 when Central Bridge received a contract from the Royal Navy to build invasion tugs. Senator William Fraser asked Herb Ditchburn to oversee the building of 156 tugs used around the harbours of Europe. The tugboats were loaded on flatcars, sent to the Trent River two miles away, then launched into the river sideways just north of the swing bridge, behind Benedict-Proctor. The tugs were numbered CT31-CT46 (built 1942), CT66-CT85 and CT130-CT205 and CT216-CT250 (built 1944)

A total of 265 ocean tugs were built by Canadian shipyards and transferred to the British Ministry of War Transport. They were officially called Canadian Tugs, with the symbol CT, but were universally known as TANACs, a name that is believed to have been intended to be the Canadian equivalent of the TUSA label used for the tugs that were built for Britain in U.S. yards. They were 60-foot, 55-ton, diesel-powered boats: all but 35 of the 265 were steel-hulled, the ten built by Smith & Rhuland in Lunenburg, NS and the 25 built by Industrial Shipping in Mahone Bay, NS being wooden-hulled. The first TANAC was delivered in late 1942 and the last in 1946. Some were returned to Canada after the war and the last few were completed after the war was over and never left Canada, but almost all of them were sold to tug operators worldwide and many are still active.

Naval historian Roger Litwiller describes the production process

this post.

"All the components of the ship were pre-fabricated on site and the finished components installed on the hull, This included cabins, wheelhouse, winches, fire-fighting equipment, etc. At peak construction, Central Bridge was producing three tugs a week. At 65 feet, the tugs were small enough to start construction inside the plant. The hulls were built upside down to make welding the steel easier. Once the hull was complete it was turned over onto a flat car and a CP engine would pull the tug out of the plant.

When the tug left the yard it was completely finished, the only stage that remained was launching. During the first year of this contract the tugs were transported to the river and launched sideways into the river, the same way as the lighters.

Again, Ditchburn’s shipbuilding experience made a dramatic change. That winter he had a long track laid from the water’s edge into the middle of the river. The entire track was built on top of the ice of the frozen river. In the spring when the ice broke up, the track sank to the bottom of the river. Divers were sent to inspect the track.

Now the tugs could be launched directly into the river. During the winter months, construction of the tugs continued and the finished ships were literally stockpiled at Central Bridge. After the ice broke up in the spring, two to three tugs a day were being launched. The tugs were moved onto a flat car and pushed to the river by a CP engine. A winch car was then placed between the engine and tug. At the water's edge, the winch was released and the flat car rolled down the track into the river. Once it reached deep enough water, the tug simply floated off the flat car and the winch then pulled the flat car back to the train. To accommodate the increase in shipbuilding a second siding was constructed into Central Bridge. The tug would travel by rail past the paper mill to the launching area located a mile further down river.

The tugs were completely finished when they were launched and the crew would start the engines and sail the ship under her own power to the dock. The CP engine would then return to Central Bridge for the next tug.

The tugs would complete their “sea trials” in the Bay of Quinte. Once accepted, they were formed into flotillas of twelve tugs and sail as a small fleet from Trenton, exiting the Trent River, crossing the Bay of Quinte and Lake Ontario. The fleet would then take the Erie Canal to New York City where they were loaded as deck cargo on a Liberty ship and transported all over the world. Several of these tugs are still in service today."

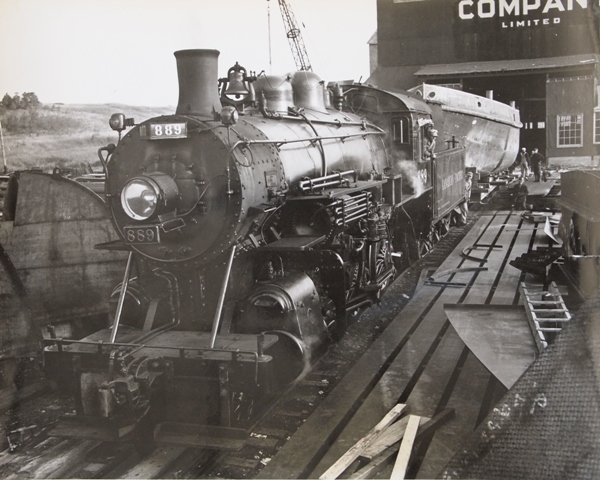

Bridge girder for the Skeena River Bridge in British Columbia:

No comments:

Post a Comment

I'm happy to hear from you. Got a comment about the Hanley Spur? Please sign your first name so I can respond better.