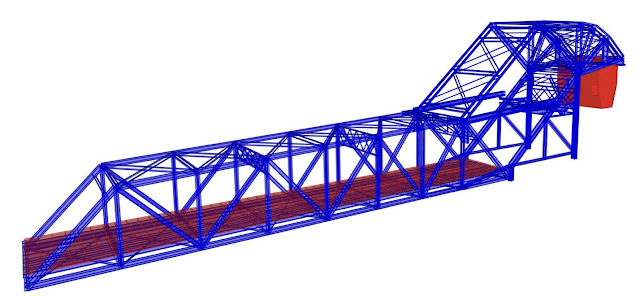

This bridge is a large and exceedingly rare example of a Strauss heel-trunnion bascule bridge in Canada. Famous engineer Joseph Strauss's single leaf heel-trunnion bridge was more common on railways, but is today rare anywhere in Canada, partially due to demolition. Compared to other Strauss heel-trunnion bascule bridges, Kingston's has a very unique appearance that makes the bridge unique. This is due to two factors. First, the rocking truss that holds the counterweight and rotates around the counterweight trunnion has more angles to it, and more diagonals extending from the counterweight trunnion that with most heel-trunnion bascule bridges. This gives this portion of the bridge a more curved appearance. Secondly, the top chord of the bascule leaf is not parallel to the bottom chord - the truss depth decreases as it extends away from the counterweight link. (Historic Bridges site)

Sitting in the middle of a causeway, the bridge is hard to ignore and is a recognizable landmark. Some alterations have been made to the bridge over the years. Some of the vertical members have what was likely originally v-lacing or lattice replaced with plate with circular holes in it. A historical photo of the bridge shows a highly ornamental bridge tender house next to the bridge at the level of the top chord. The house is no longer in place. The current bridge tender control house is located at ground level at the northwest quadrant around the bridge. Inside, it contains modernized operating control panels for the bridge. The concrete counterweight has had steel paneling added around it.

- The 1829 “Penny Bridge,” a wooden toll bridge with a swing section to allow passage of marine vessels. In May of 1911, The Cataraqui Bridge Co. had conveyed its dilapidated Penny Bridge to the city, who in turn ceded title to the Department of Public Works in June, 1912. Begun in 1826, Penny Bridge bridge shares were sold for $100 to raise the $24,000 needed for its construction. At 25 feet wide and 1,800 feet long, the bridge opened for traffic in 1829, charging a penny per pedestrian.

- 1917: A single-leaf Strauss heel trunnion design of the Strauss Bascule Bridge Co. of Chicago was built by the Hamilton Bridge Co. “Trunnion” is a French word for “pivot point.” A trunnion bridge pivots like a see-saw around a central core. This is a key operational component of the bridge that requires regular scheduled overhauls to ensure ongoing operations.The original East Bridge and West Bridge were single-span through truss structures in 1917.

- 1966: The Bascule Bridge operating mechanism was renewed, including a new operator’s cabin and control electronics.

- 1968-69: The East Bridge was replaced with a two-span pre-stressed concrete slab beam bridge designed by C.C. Parker & Associates Ltd. Construction of the roadway bypass allowed the eastern span of the bridge to be raised to 13'6" to allow more vessels to bypass the main liftable span. The work was contracted to Master Craft Bridge and Engineering Construction (Ottawa) Limited. At the time, the causeway was handling 12,000 car trips per day, with numbers expected to increase to 25,000 by 1981 and a second bridge crossing of the river was already being called for. Before replacement, perhaps a good fishing spot (below - Queen's University Archives, Kingston Whig-Standard Fonds V142.3-160):Below-March 25, 1969(Queen's University Archives, Kingston Whig-Standard Fonds,V142.6.288)

- 1973: The Bascule Bridge floor beams were replaced with welded wide flange beams.

- 1981: The Bascule Bridge floor system stringers were replaced, along with the timber sidewalk stringers and deck planks.

- 1994: The West Bridge was replaced with a 2-span pre-stressed concrete box beam girder bridge.

- 2001: Two buffers were added to the Bascule Bridge to reduce impact when the bridge lands.

- 2004: A maintenance contract on the Bascule Bridge was completed to replace rivets in fatigue- prone members of the counterweight.

- 2009-2013: The Bascule Bridge underwent a major rehabilitation, which included: removal of lead paint; structural repairs to deteriorating steel members (i.e. operating arm, bottom gusset plates, exterior splice plates in the bottom chord, etc.); reinforcing certain diagonal truss members; replacing timber sidewalk stringers and deck planks; installation of new pedestrian railing; replacing traffic barrier; and replacing wood stairway treads with steel treads; installation of a new steel counterweight for balancing the bridge.

- 2017: Replacement of the buffers; detailed inspection and repair options report for the steel deck grating; repairs to the span locks and bottom chords of the leaf truss; upgrades to the motor drive and motor control upgrade; rehabilitation of the guide assemblies.

- 2020: Mechanical systems were repaired to address the systems’ deficiencies that impacted operations.

- 2021: Structural steel was repaired to address fatigue issues in the structural truss.

- 2022: Concrete repairs were completed to address deficiencies on the road and critical structural items for the health and safety of the public.

- 2023 : Bridge deck replacement, trunnion steel rehabilitation and counterweight rehabilitation were underway.

- 2024: The trunnion was damaged during the re- construction on Saturday, March 30 at 5 p.m. The steel is believed to have become too fatigued to continue with load bearing pressures.

- 1967 collision S.S. Baygeorge

- Then and Now views

- a grandiose Foot-of-the-Lakes Terminal plan

Thanks for posting this. A shame that it had to be demolished. Hopefully the replacement is similar.

ReplyDeleteIt happened very quickly, Eric. Not quickly enough for the dry dock and cruise boats docked there. Navigation has been restored, though continuing it through construction will be challenging!

ReplyDeleteThanks for your comment,

Eric

Thanks for your comments, Eric and A. I think this is only the beginning of the next Bridge Saga, or should we say the next phase in the causeway's significant history!

ReplyDeleteEric